Name: Packwell Solutions

Tel: 07104-222888

Mob: +919158666881

E-mail: Info@packwellsolutions.com

Add: A-14, Plot no. B-2 & B-3, Flatted Building, MIDC Area, Nr. Vasudev Nagar Metro Station, Ambazari Hingna Road, Nagpur Area, Maharashtra, India

GST:

27AALPO1712A1Z5

|

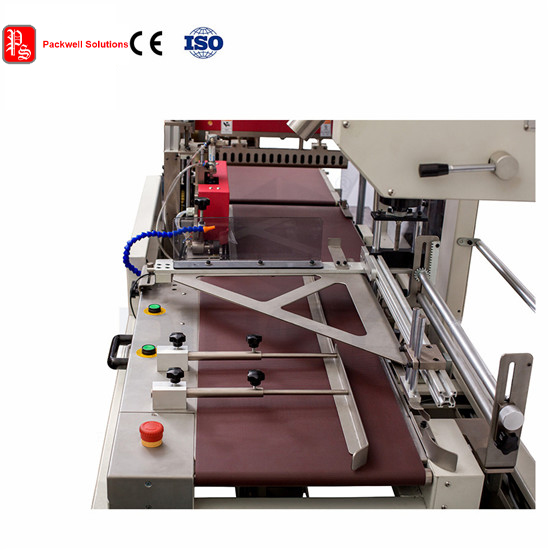

Product name : Automatic side sealing machine

Item : DQL4518 & DSC4520L

:

:

|

| Details: | ||||||||||||||||||||||||||||||||||||

DQL4518 automatic side sealing machine characteristic: 1. DQL4518G is the automatic side sealing machine which developed by ourselves, it is used to high capacity packing production line, feeding, conveying, entering bag, sealing can be finished at a time, it has high working efficiency. 2. Vertical sealing adopts high quality supporting structure and two sides linear guideway to make sealing pressure balanced, frame won’t be damaged easily. The sealing knife adopts copper alloy sprayed with teflon, it won't stick film, sealing fastness, without smoke, non-pollution 3. Side sealing adopts constant temperature sealing knife, sealing part is straight and strong, there is no limited about packing object length. Film feeding belt adopts widen and thicken belt, its using life is long and easily to be replaced. 4. Machine adopt PLC controller, it is equiped with horizontal and vertical photo sensor to reach high speed and automatic working. 5. It is easy to change the size, just need adjust the handle, operation is easy. 6. It can be connected with a production line 7. it has protection function to avoid sealing product wrong and ensure the safety of operator 8. Optional function is front inlet feeding conveyor.

DSC4520L shrink tunnel characteristic: 1. It adopts Schneider AC contactor, high-power Solid-state booster and intelligent temperature controller to make temperature system more accurate, prolong the working life. 2. It adopts solid roller conveyor, the rollers wrapped with high temperature silica gel tube. It can stand heavy product and difficult abraded (you can choose net type conveyor) 3. Solid roller rotate with conveying chain, at the same time solid roller rotate by itself, down side sealing effect of object won’t affect by roller, each side sealing effect is firm. 4. It adopts high-power fan motor to ensure enough strong wind to reach perfect packing effect. 5. Inside wall adopts stainless steel, temperature transfer is uniform, heat loss is little. Two sides have adjusting door, it can be adjusted according to the shape of object to reach the best shrink effect. 6. Application: This machine is widely used in photo frame, aluminum profile, water pipe, wood floor, and other industries shrink packaging. It is suit POF, PE, PVC and other Machine Spare Parts

.

Specification:

|

||||||||||||||||||||||||||||||||||||

| Related Products : |

Air Cushion Machine

Air Cushion Machine