Control System

* PLC control

*Photo-eye auto-height sensing pallet height

*Separate top ,bottom & up-down Wrap Counter options

*Overwrap time is up to create an overwrap

*Reinforce wrap times is set to better secure 2 loads placed on top of each other

*Film Tension Control adjustment on the panel

*Separate start, pause and emergency stop buttons

*Manual carriage up/down

*Variable Turntable Speed

*Carriage up/down speed control

*Manual/automatic exchangeable

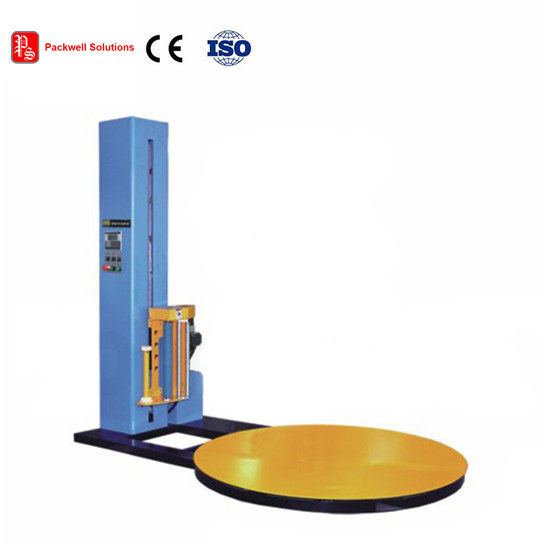

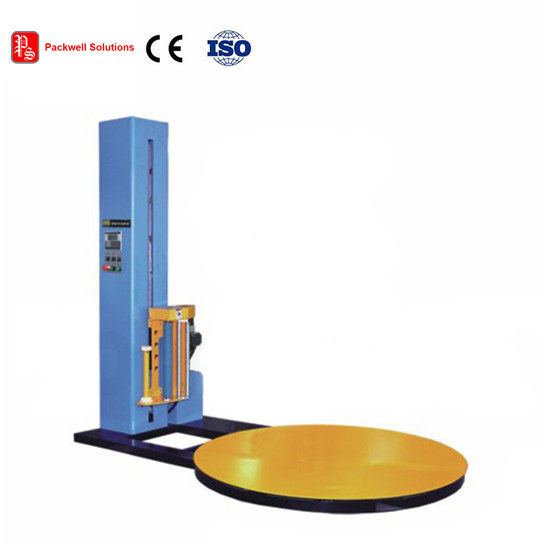

Turntable

*1650mm Diameter Structural steel plate

*85mm Height floor to top of turntable

Turntable drive

*0-12rpm variable turntable speed by frequency changer

*Position turntable alignment

* works under speed 0.75 kw motor with reduction gearbox ,Soft start

Film carriage

*Powered pre-stretch system up to 250% to min film consumption

*Carriage door opens for effortless roll change and thread film

*Film delivery variable speed by separate DC Drive Motor

*Electronic film tension control adjustment on panel

*Film dancer-bar with variable speed output

Film carriage Drive

*Heavy duty double-chain carriage lift, calm and safety

*Film carriage variable speed by frequency changer

*works under 0.23 kw motor with reduction gearbox

Technical Parameter

|

(L*W) Wrapping Size

|

(500~1200)mm ×(500~1200)mm

|

|

Wrapping Height

|

L model 1800mm H model 2400mm

|

|

Working Capability

|

20~40CTNS/ HOUR 0-12rmp/second

|

|

Board Size

|

φ1500mm&1650mm , H85mm

|

|

Loadable Weight

|

(max)2000Kg

|

|

Film carriage system

|

Pre-stretch film carriage, auto convey the film,

|

|

up-down frame

|

Double chain, adjustable speed

|

|

Controller

|

PLC control,overwrap layers adjustable,Pre-stretch film carriage

|

|

Power/Voltage

|

1.35KW/AC220V

|

|

Material (thickness, width )

|

PE T17~35um ,W500mm

|

|

Weight

|

750K

|

Air Cushion Machine

Air Cushion Machine